Benefits of installing CJC® Filtration

- Eliminate 3 out of 4 shutdowns

- Extend oil lifetime with a factor 4

- Reduce spare parts consumption by up to 60%

- Reduce risk of unforeseen breakdowns, repairs and maintenance

- Protect your investment

When CJC® Offline Oil Filters have been installed on crushers, there is no need to shovel dirt out of the tanks!!

Given the rough operating conditions for a crusher, it is common to believe that you need to change oil frequently – sometimes every quarter; or in some cases even more often.

A crusher breakdown is extremely expensive when measured in lost production, so operators will rather change the oil too frequently than run the risk of unforeseen breakdowns. Typically oil changes happen every three to four months in order for the operation to run – a very costly and unnecessary measure, especially since production is put on hold during the oil change. In some cases, you may need to shovel out dirt from the oil reservoir during oil change intervals.

In terms of servicing the filter, the high volume of particles in the environment pose a risk of high costs for replacing clogged filter insert too often, if dirt holding capacity is low.

CJC® Reduce oil change intervals and wear on crusher components brochure

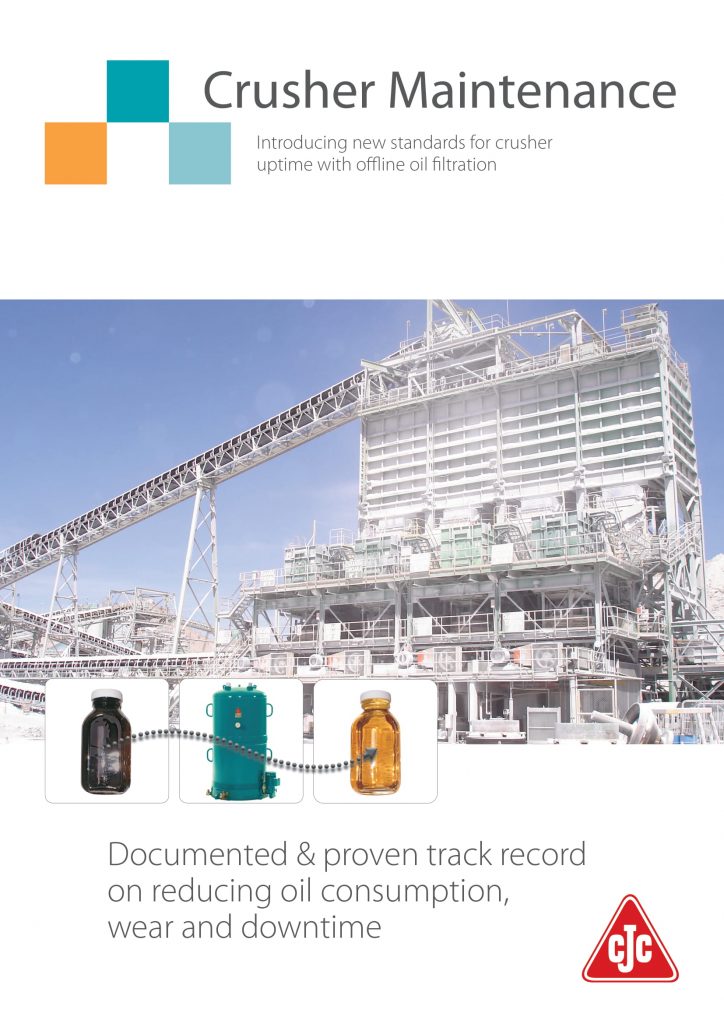

CJC® Crusher Maintenance Brochure

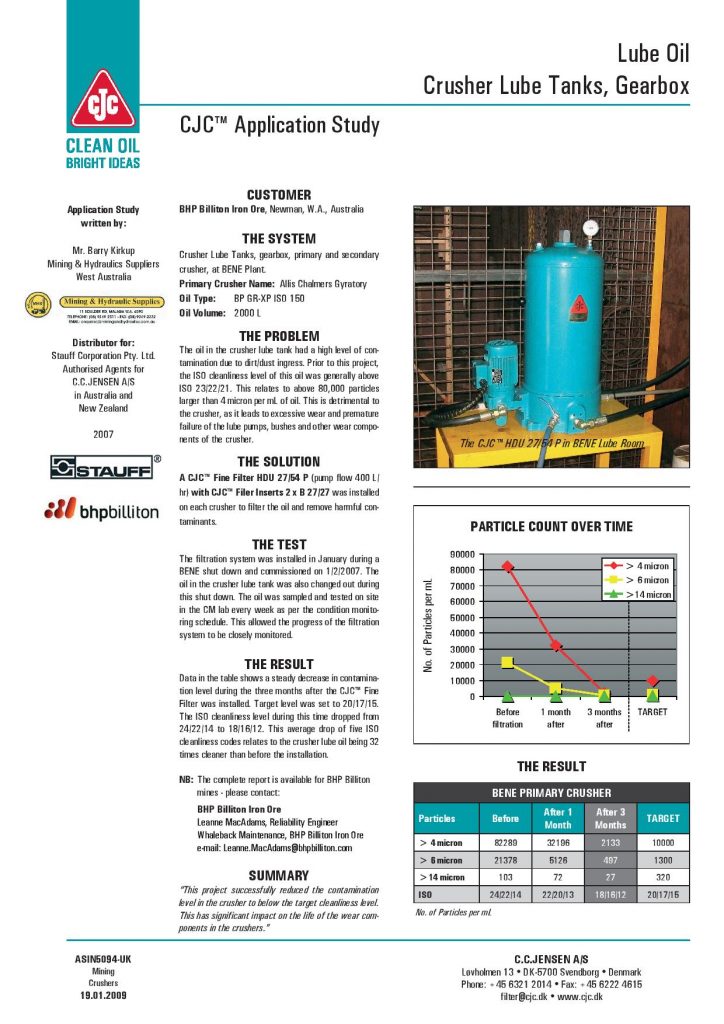

Client: BHP Billiton Iron Ore

System: Crusher Lube Tanks, Gearbox Primary & Secondary, Gyratory Crusher.

Oil: 2000L ISO 150

ISO Prior to CJC®: 24/22/14

ISO After CJC®: 18/16/12

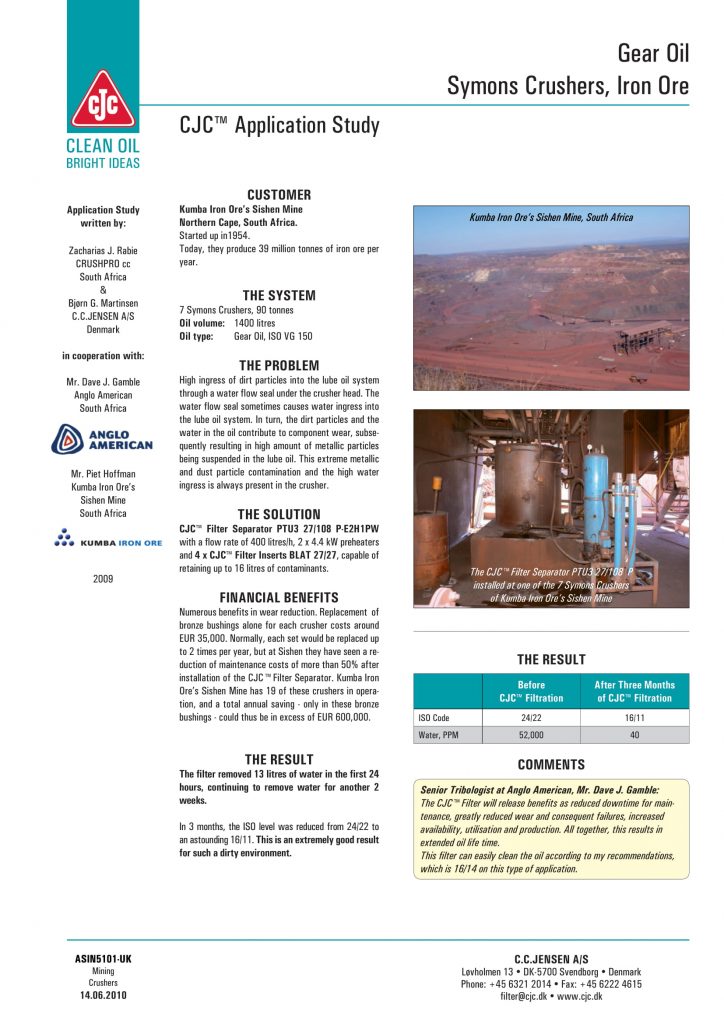

Client: Anglo American

System: 7 Symons Crushers, 90 Tonnes

Oil: 1400L ISO 150

ISO Prior to CJC®: 24/22

ISO After CJC®: 16/11

Client: BHP Billiton

System: Primary Cruhser FLSmidth Fuller-Traylor Gyratory Crusher

Oil: 4000L ISO VG 320

Shutdowns Prior to CJC® P/A: 6

Shutdowns After After CJC® P/A: 1

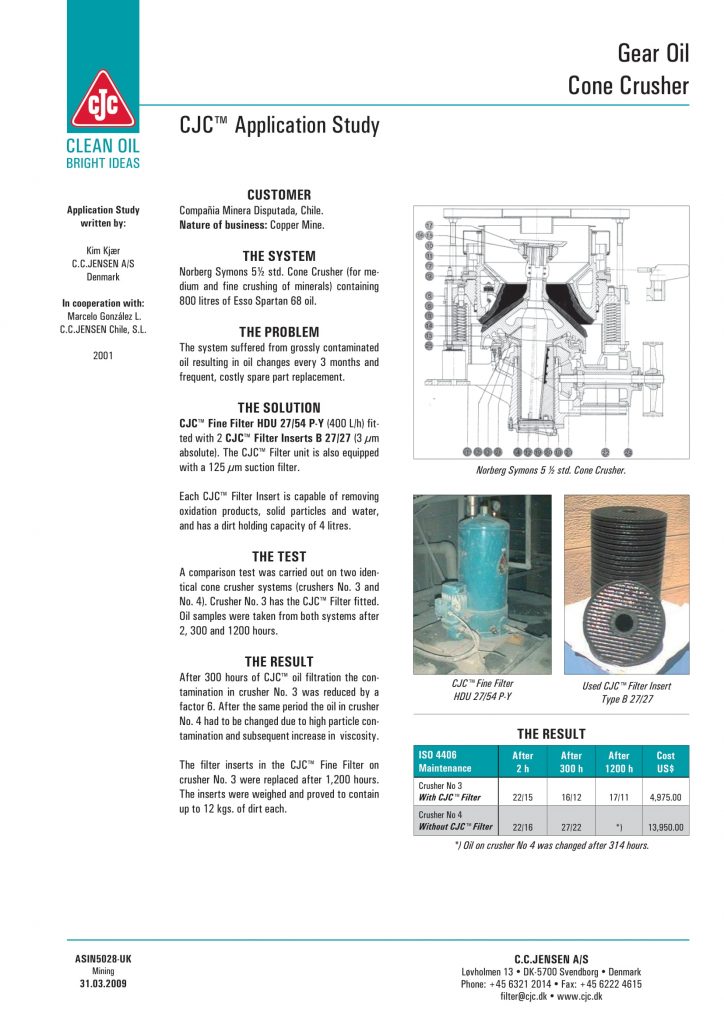

Client: Compañia Minera Disputada, Copper Mine

System: Norberg Symons 5½ std. Cone Crusher

Oil: 800L ISO 68

ISO Prior to CJC®: 22/15

ISO After CJC®: 17/11

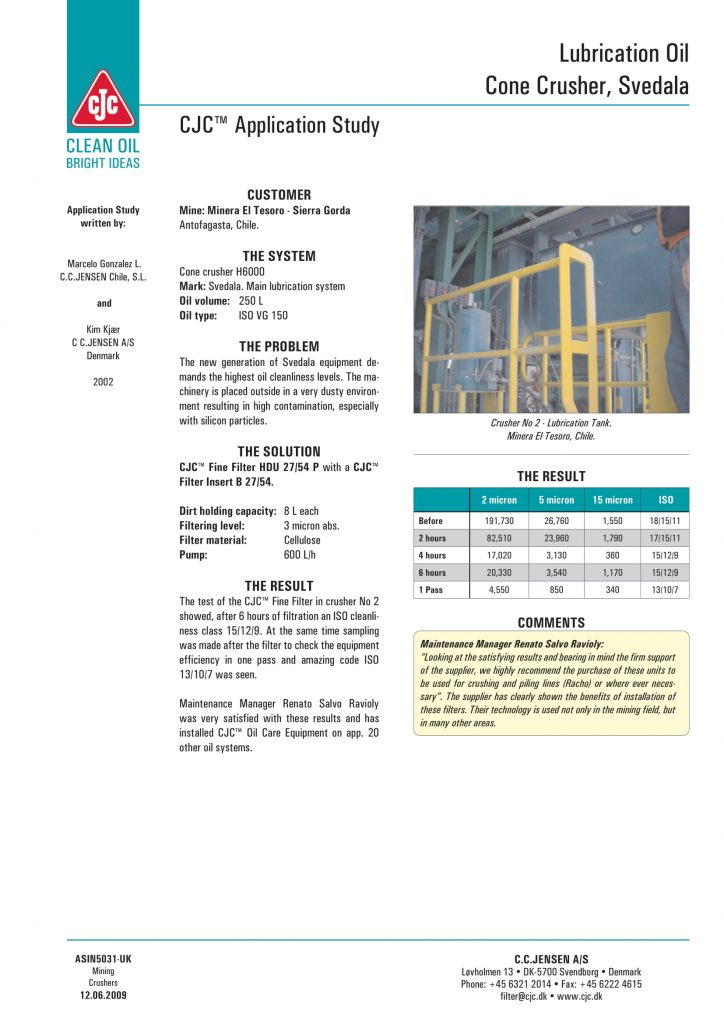

Client: Minera El Tesoro – Sierra Gorda

System: Svedala H6000 Cone Crusher, Main Lubrication System

Oil: 250L ISO 150

ISO Prior to CJC®: 18/15/11

ISO After CJC®: 13/10/7

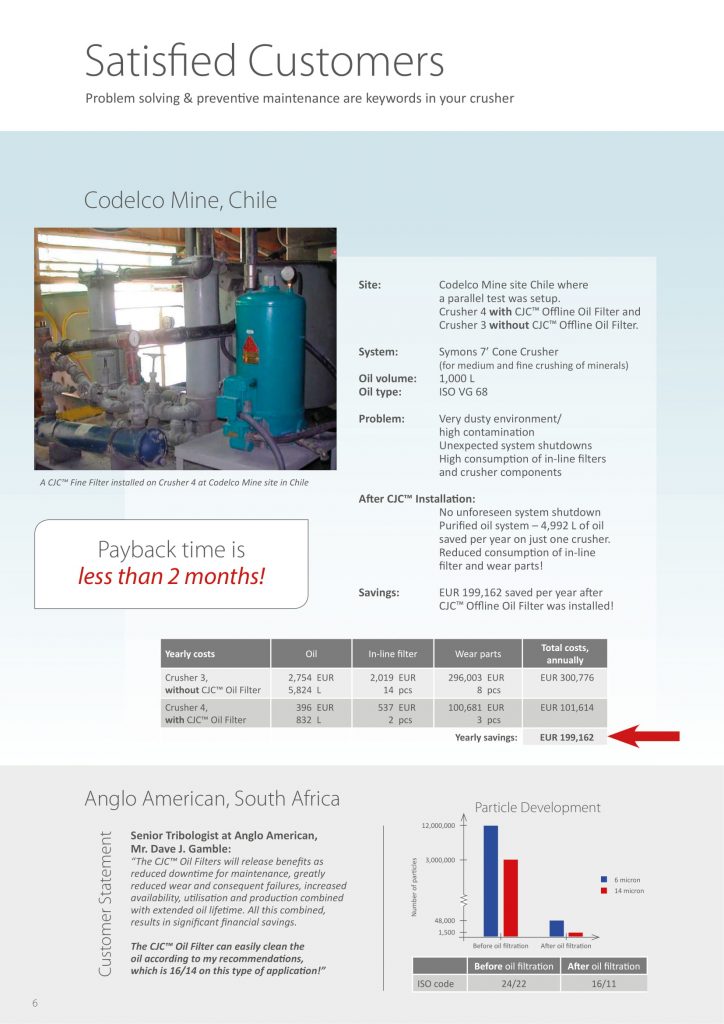

Client: Anglo American

System: 7′ Symons Crushers

Oil: 1000L ISO 68

ISO Prior to CJC®: 24/22

ISO After CJC®: 16/110

CJC® Fine Filters are offline oil filtration solutions with integrated circulating pumps for off-line installation. The filters are recognized around the world as highly efficient purification systems for applications involving hydraulic oil, lubrication oil, gear oil, quenching oil, phosphate esters and more.

CJC® Fine Filters are ideal for controlling oil contamination levels for particles, water and degradation products (oxidation resin/sludge, varnish).

CJC® Desorbers are patented products designed to remove water from oil types which either bind and emulsify water or are high viscosity oil (up to ISO VG 1000). CJC® Desorbers are ideal for use in applications in which water ingress is a continuous and significant problem, whether for lubrication oil, gear oil or hydraulic oil.

CJC® Desorbers heat oil slightly before it meets a counter flow of cool air in the desorber housing. Air heated by the oil expands, drawing water from the oil. The subsequent air-cooling condenses the water and the dry air is re-used for removing water from incoming oil.