Benefits of installing CJC® Filtration

- Keeps your quench works fit for operation

- Ensure cleaner processed parts

- Keeps the quench oil free from particles and oxidation residues

- Reduce risk of unplanned breakdowns and maintenance

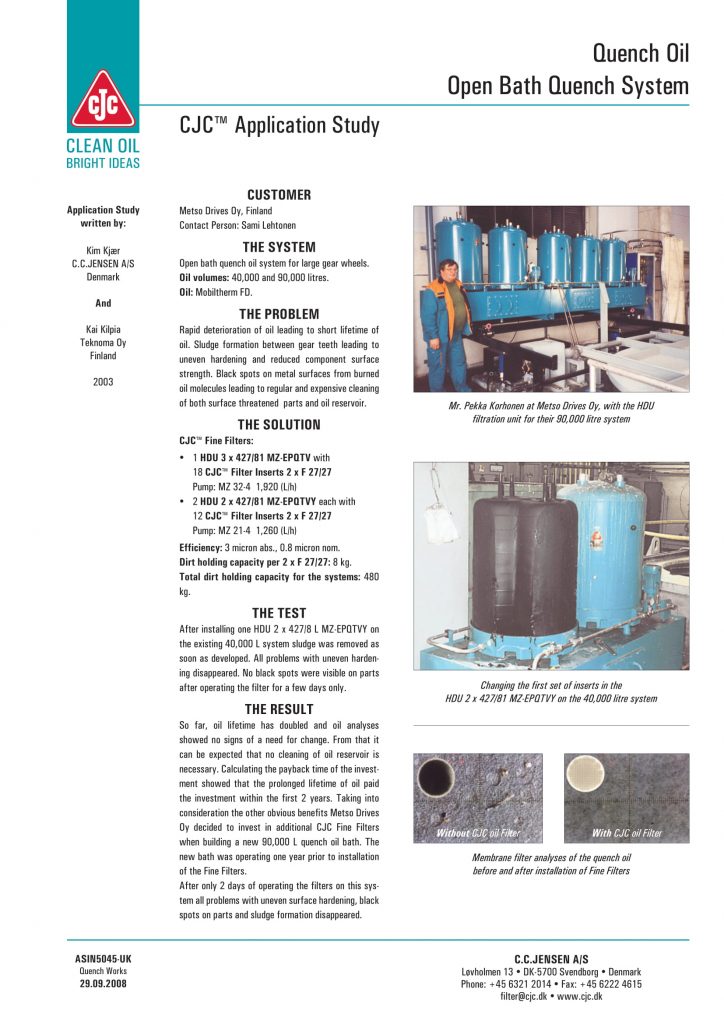

Choosing CJC® Oil Filtration, you ensure a long lifetime of the Quench Oil, maintain the quality of the quenching process and avoid unplanned shutdowns

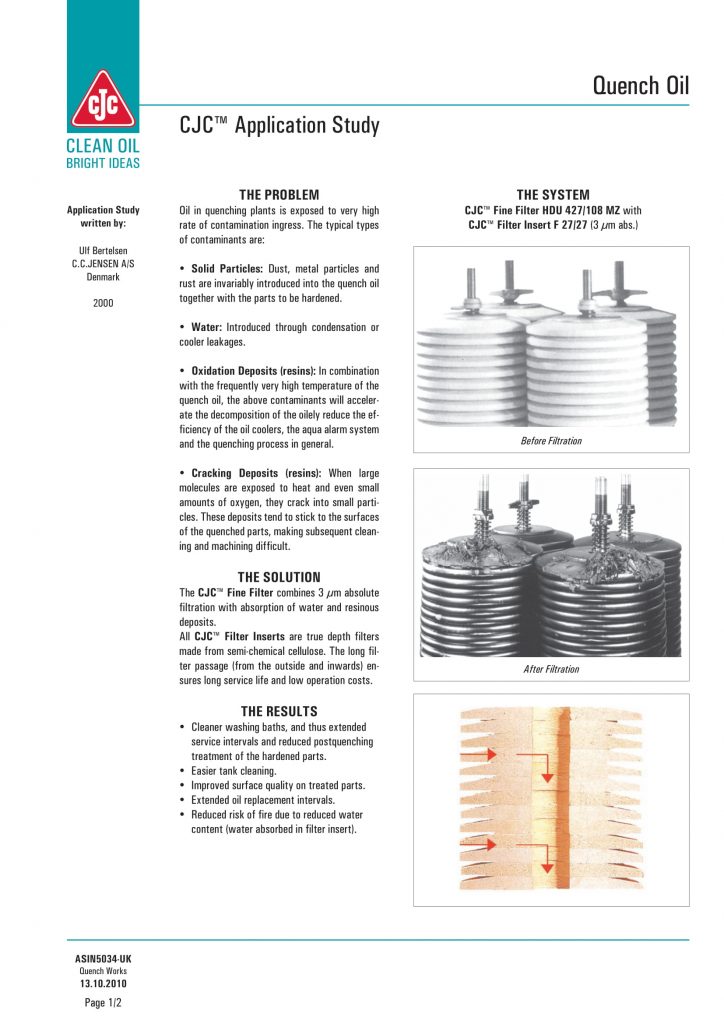

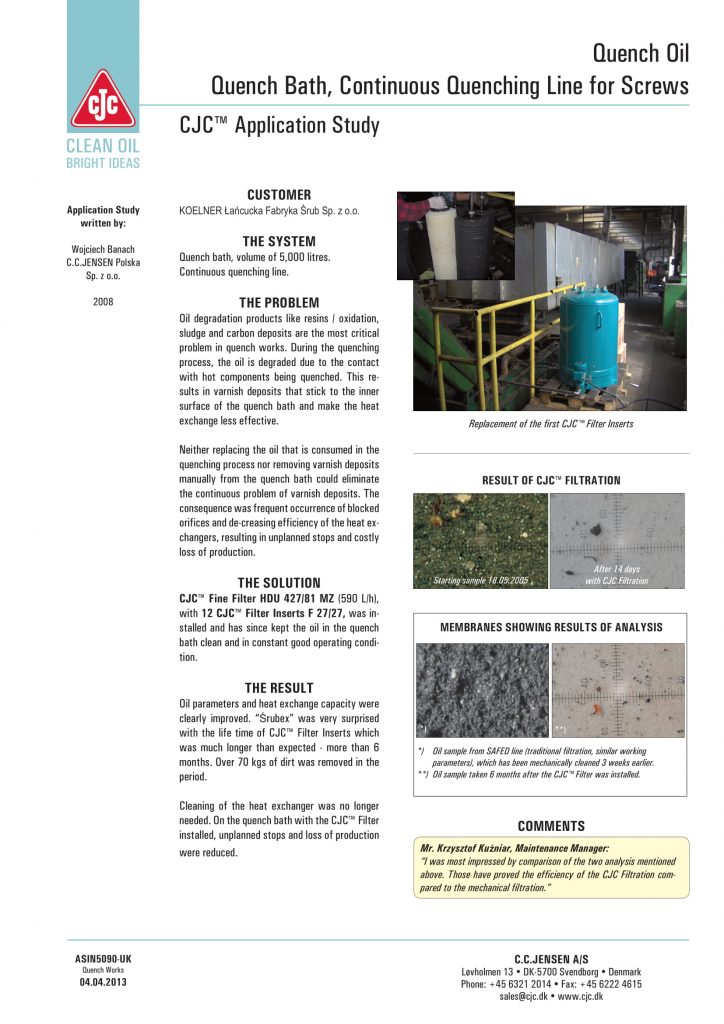

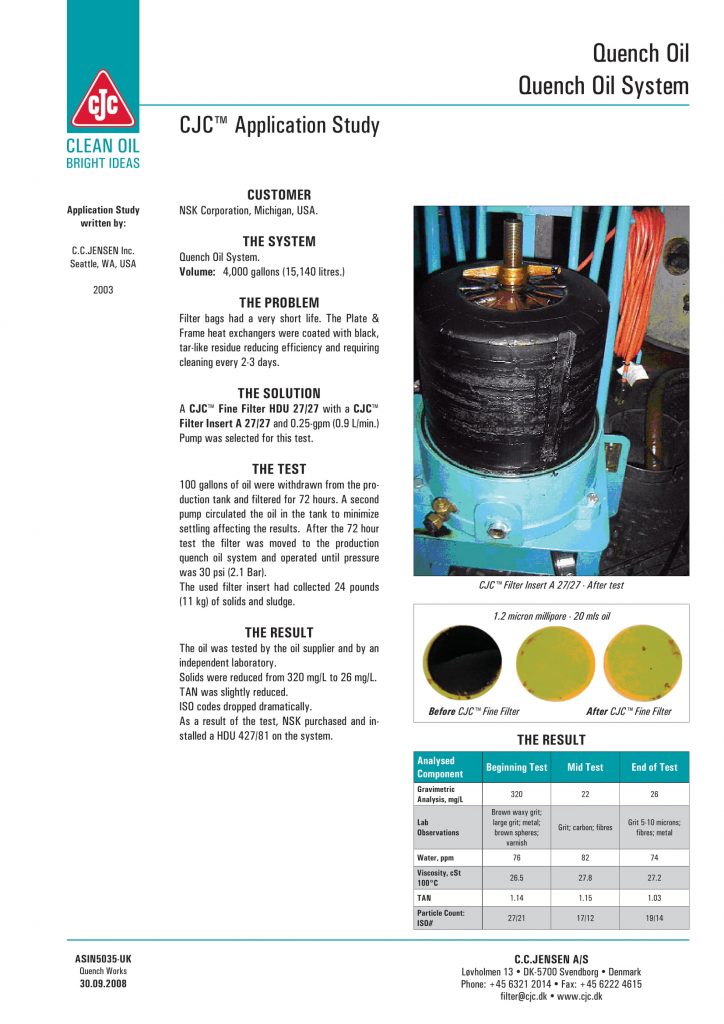

Oil degradation products and the consequent oxidation by-products are other typical contamination sources due to high temperatures. CJC® Depth Oil Filtration is a highly effective way to remove particle contamination, water contamination and oil degradation products – all in one process. Changed cooling curve when oil is contaminated with carbon deposits will result in lower quality of processed parts.

CJC® Fine Filters are offline oil filtration solutions with integrated circulating pumps for off-line installation. The filters are recognized around the world as highly efficient purification systems for applications involving hydraulic oil, lubrication oil, gear oil, quenching oil, phosphate esters and more.

CJC® Fine Filters are ideal for controlling oil contamination levels for particles, water and degradation products (oxidation resin/sludge, varnish).

CJC® Desorbers are patented products designed to remove water from oil types which either bind and emulsify water or are high viscosity oil (up to ISO VG 1000). CJC® Desorbers are ideal for use in applications in which water ingress is a continuous and significant problem, whether for lubrication oil, gear oil or hydraulic oil.

CJC® Desorbers heat oil slightly before it meets a counter flow of cool air in the desorber housing. Air heated by the oil expands, drawing water from the oil. The subsequent air-cooling condenses the water and the dry air is re-used for removing water from incoming oil.