Benefits of installing CJC® Filtration

- Keeps your machinery and tools fit for operation

- Keeps the gear oil free from particles and oxidation residues

- Maintain high process stability and efficiency

- Ensure product quality

- Reduce risk of unplanned breakdowns and maintenance

- Extend gear and machine oil lifetime with a factor 3-4

When you choose CJC® Oil Filter, you reduce maintenance costs and avoid unplanned breakdowns, and you optimize output

If the oil in the steel work – eg. main gear lubrication, central bearing lubrication, oven hydraulics – is not kept clean and free from oxidation particles, you risk expensive down time, loss of efficiency in the supply chain and lower output. If the oil in the process gears is not clean, you risk quality problems and higher scrap rates. If oil is contaminated with particles, you will experience extra wear on the gears, and the risk of unplanned breakdowns will increase dramatically because of the high volume of particles in the moulding process. In the machining processes on hydraulic machines, oil that is not clean will lead to unplanned standstills and shorter lifetime of machinery.

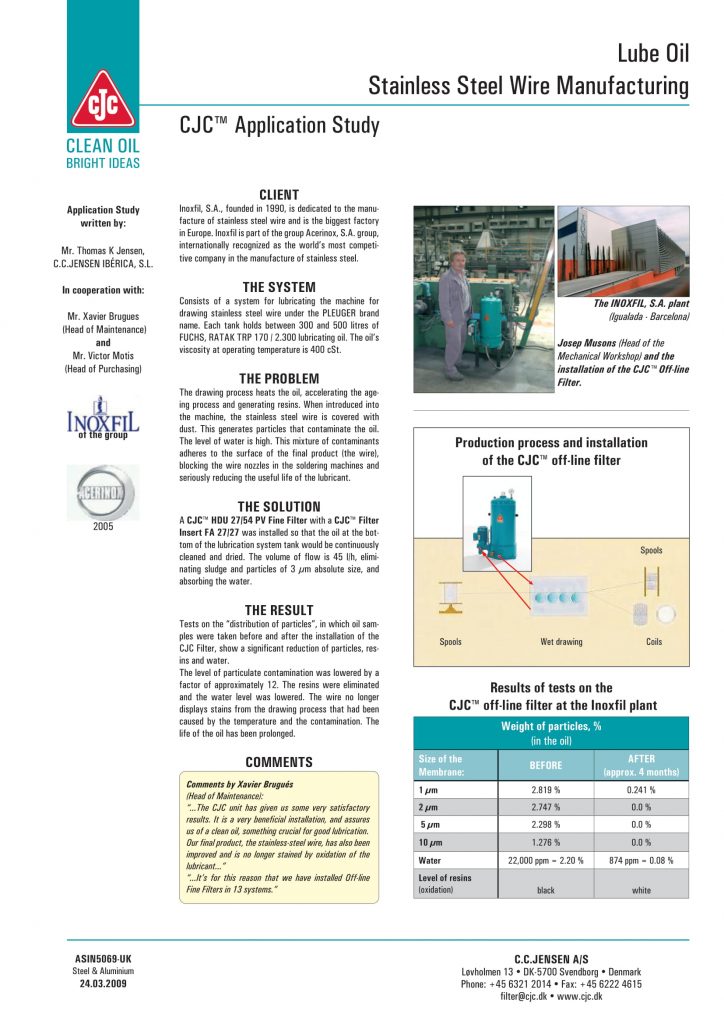

System: Lubrication System for machine drawing stainless steel wire

Oil: 500L Lube OIl

Water PPM Prior to CJC®: 22,000

Water PPM After CJC®: 874

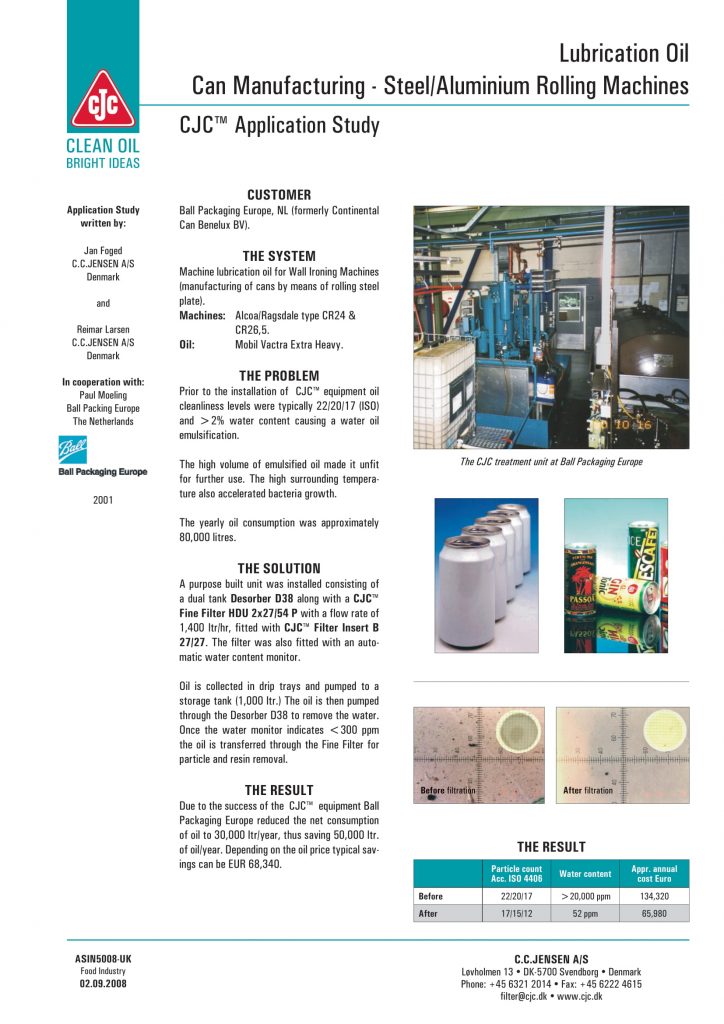

System: Lubrication System for wall ironing machines

Oil: Mobil Vactra Extra Heavy

ISO Prior to CJC®: 22/20/17

ISO After CJC®: 17/15/12

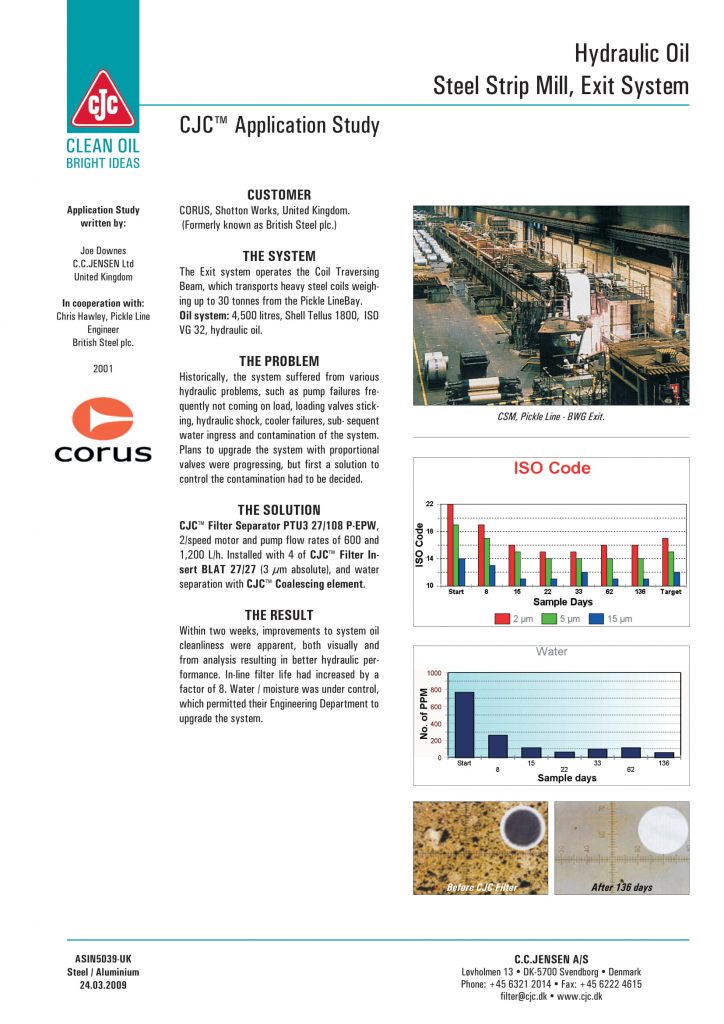

System: The exit system operates the coil traversing beam, which transports heavy steel coils.

Oil: 4500L ISO VG 32

ISO Prior to CJC®: 22/19/14

ISO After CJC®: 16/14/11

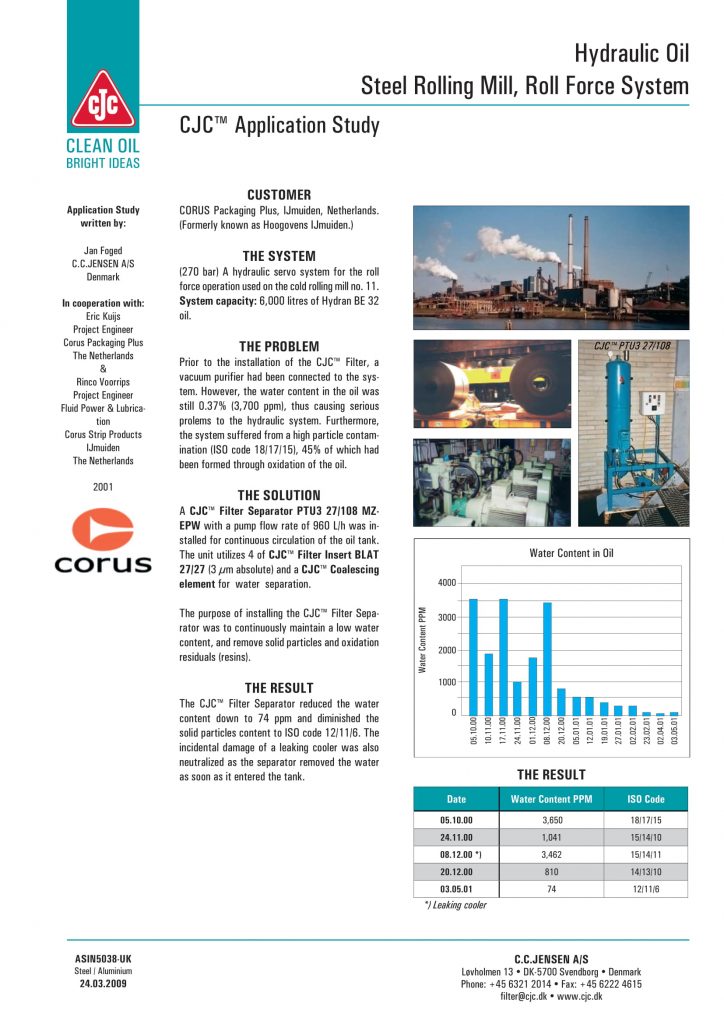

System: A hydraulic servo system for the roll force operation used on the cold rolling mill no. 11.

Oil: 6000L ISO VG 32

ISO Prior to CJC®: 18/17/15

ISO After CJC®: 12/11/6

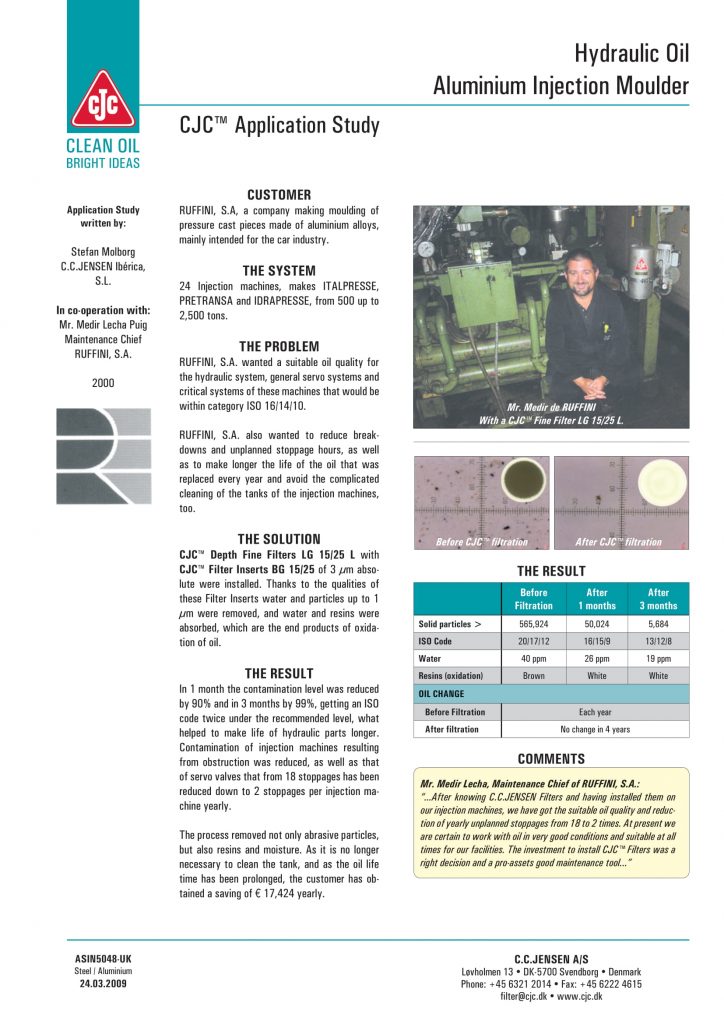

System: 24 Injection Machines

Oil: 4000L ISO VG 320

ISO Prior to CJC®: 20/17/12

ISO After CJC®: 13/12/8

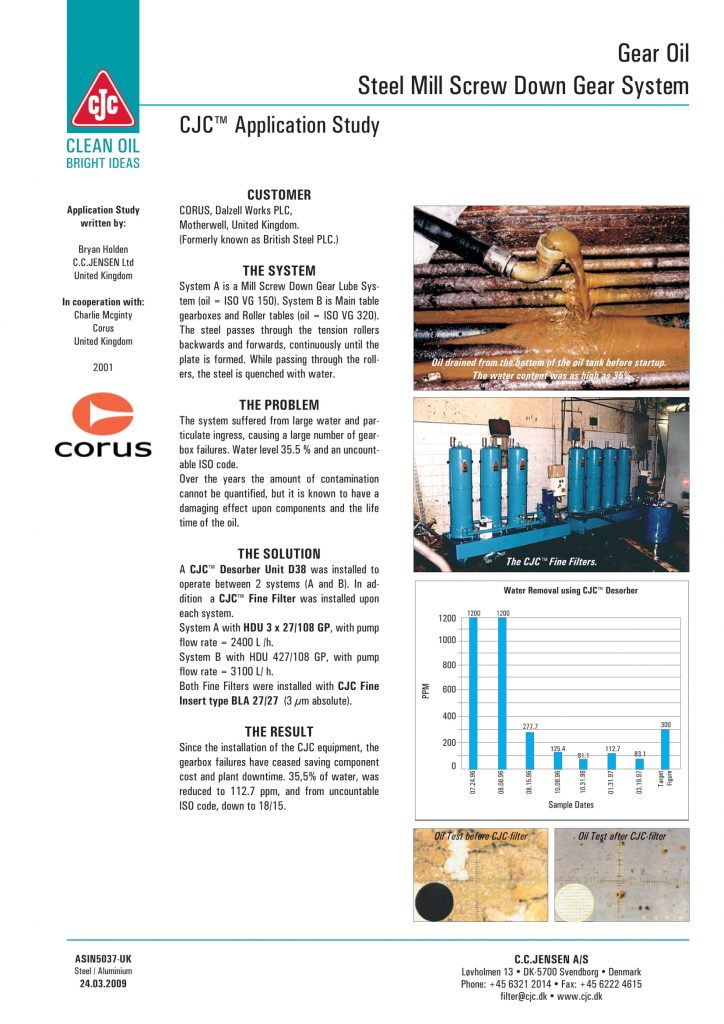

System: Steel Mill Screw down gear system

Oil: ISO VG 150 – ISO VG 320

Water PPM Prior to CJC®: 1,200

Water PPM After CJC®: 83

System: Slewing Gear drives, Ore bucket digger

Oil: 100L ISO VG 220

Water PPM Prior to CJC®: 62,970

Water PPM After CJC®: 29.9

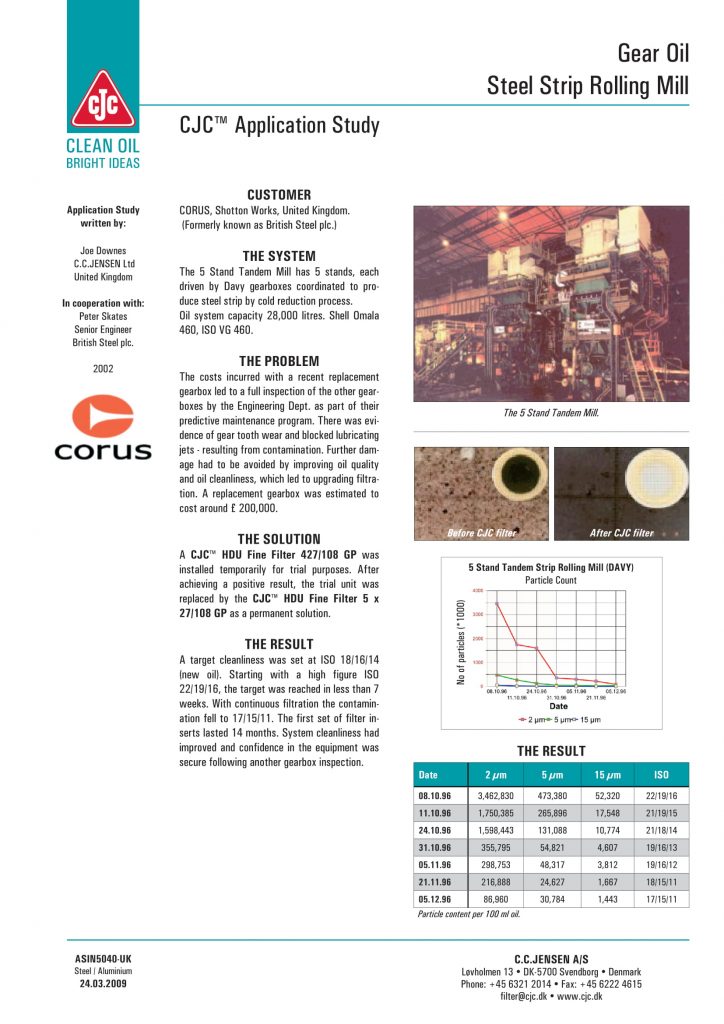

System: Steel strip rolling mill

Oil: 28,000 ISO VG 460

ISO Prior to CJC®: 22/19/16

ISO After CJC®: 17/15/11

CJC® Fine Filters are offline oil filtration solutions with integrated circulating pumps for off-line installation. The filters are recognized around the world as highly efficient purification systems for applications involving hydraulic oil, lubrication oil, gear oil, quenching oil, phosphate esters and more.

CJC® Fine Filters are ideal for controlling oil contamination levels for particles, water and degradation products (oxidation resin/sludge, varnish).

CJC® Filter Separators are offline oil filtration solutions / oil separators, combining fine filtration with water separation all in one unit, with an integrated circulating pump. They are designed for use in applications containing hydraulic oil, diesel fuel, lubrication oil, etc., in which water ingress is a constant or recurrent problem.

CJC® Filter Separators remove water by coalescence and at the same time minimize oil contamination levels of particles and oil degradation products (oxidation resin/sludge, varnish).