Benefits of installing CJC® Filtration

- Increased Availability

- Reduced Maintenance Budget

- Fewer unplanned breakdowns and stops of production

- Enhanced operational precision

- Improved profitability

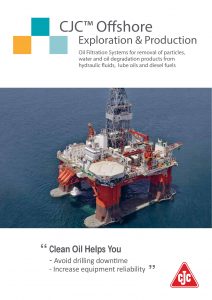

Clean Oil helps you avoid drilling downtime due to breakdowns, thus increasing your equipment reliability!

We know the importance of uptime and how to reduce the risk of expensive breakdowns. With CJC® Oil Filters installed on your Offshore Rig, you effectively reduce oil-related problems, and you ensure always having continuous clean & dry oil providing the best operation and efficiency, giving you the highest earnings.

CJC® Oil Filters constantly remove particles, water and oil degradation products from oil, resulting in reduced wear on components in many different marine and offshore applications. This extends the lifetime of the lubrication and hydraulic oil with a factor 3-4, improving your uptime. We clean diesel to a level optimized for common rail technology.

CJC® Fine Filters are offline oil filtration solutions with integrated circulating pumps for off-line installation. The filters are recognized around the world as highly efficient purification systems for applications involving hydraulic oil, lubrication oil, gear oil, quenching oil, phosphate esters and more.

CJC® Fine Filters are ideal for controlling oil contamination levels for particles, water and degradation products (oxidation resin/sludge, varnish).

CJC® Desorbers are patented products designed to remove water from oil types which either bind and emulsify water or are high viscosity oil (up to ISO VG 1000). CJC® Desorbers are ideal for use in applications in which water ingress is a continuous and significant problem, whether for lubrication oil, gear oil or hydraulic oil.

CJC® Desorbers heat oil slightly before it meets a counter flow of cool air in the desorber housing. Air heated by the oil expands, drawing water from the oil. The subsequent air-cooling condenses the water and the dry air is re-used for removing water from incoming oil.